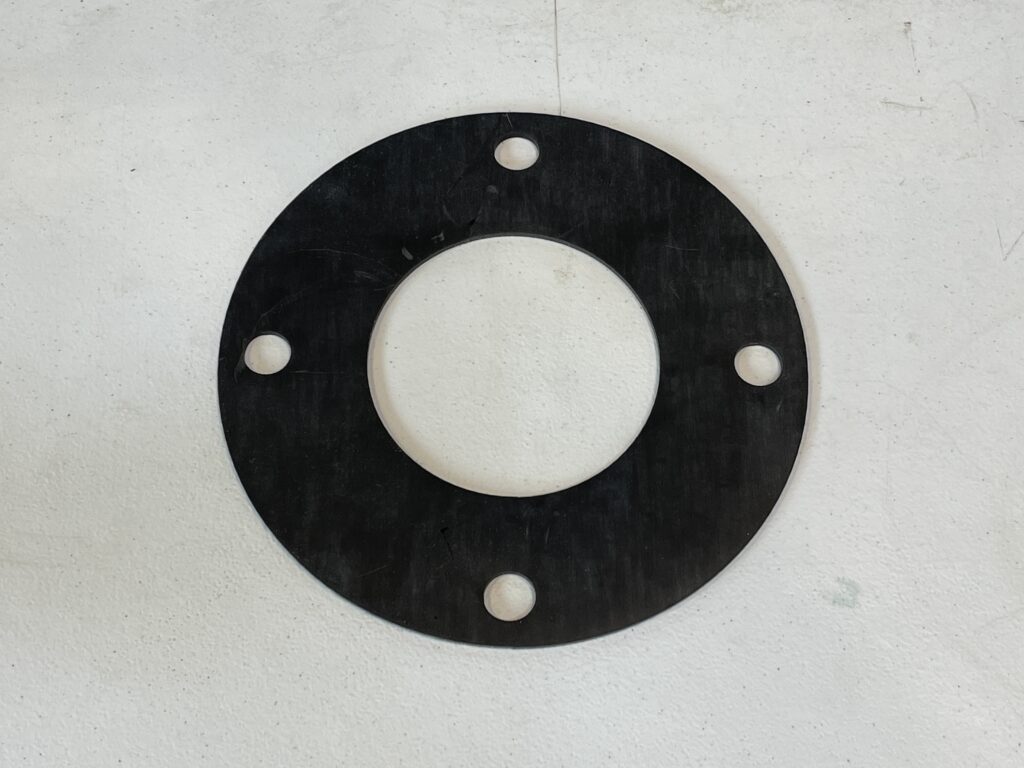

PEEK GASKETS

Peek gaskets are highly durable and resistant to high temperatures, chemicals, and wear, making them ideal for use in demanding industrial applications where reliability and performance are critical. Additionally, Peek gaskets offer excellent sealing properties, providing a high-performance sealing solution for applications such as in the aerospace, automotive, medical, and oil and gas industries, where high-pressure and high-temperature environments are common.

Common applications for Peek gaskets

Automotive industry: Peek gaskets are useful due to their excellent resistance to high temperatures and chemicals, and they are used in critical applications such as in engines, transmissions, and fuel systems, ensuring improved performance, fuel efficiency, and reduced emissions.

Aerospace industry: Peek gaskets are useful due to their high strength and resistance to high temperatures, chemicals, and wear, and they are used in critical applications such as in aircraft engines, fuel systems, and hydraulic systems, ensuring improved safety and reliability.

Construction industry: Peek gaskets are useful due to their durability and resistance to high temperatures and chemicals, and they are used in critical applications such as in industrial boilers, pipelines, and heat exchangers, ensuring improved efficiency and minimizing the risk of leaks.

Electrical industry: Peek gaskets are useful due to their electrical insulation properties and resistance to high temperatures and chemicals, and they are used in critical applications such as in transformers, generators, and circuit breakers, ensuring improved safety and reliability of electrical equipment.

Food and beverage industry: Peek gaskets are useful due to their high strength, chemical resistance, and ability to maintain a reliable seal, and they are used to ensure hygienic and secure sealing of food processing equipment such as pumps, valves, and heat exchangers.

Medical industry: Peek gaskets are useful due to their high strength, chemical resistance, and ability to maintain a reliable seal, and they are used in medical devices such as pumps, valves, and analytical equipment, ensuring improved patient safety and minimizing the risk of contamination.

Oil and gas industry: Peek gaskets are useful due to their high strength and resistance to high temperatures, chemicals, and wear, and they are used in critical applications such as pipelines, refineries, and drilling equipment, ensuring improved safety and efficiency.

Pharmaceutical industry: Peek gaskets are useful due to their high strength, chemical resistance, and ability to maintain a reliable seal, and they are used in critical applications such as reactors, filtration systems, and drug manufacturing equipment, ensuring regulatory compliance and minimizing the risk of contamination.

Water treatment industry: Peek gaskets are useful due to their high strength and resistance to high temperatures and chemicals, and they are used in critical applications such as pumps, valves, and piping systems, ensuring efficient and reliable water treatment processes while minimizing the risk of leaks and contamination.

- HVAC industry: Peek gaskets are useful due to their high strength and resistance to high temperatures and chemicals, and they are used to seal ductwork and other components, ensuring energy efficiency and preventing air leakage.

OUR CAPABILITIES

Whether it be in small test batches with one of our CNC Knife Cutting Machines or with large scale production on one of our premium Die Cutting Machines, American Cutting Solutions is uniquely equipped to supercharge your production, converting, and supply chain process.